BeatBox Beverages 2022/2023 Sustainability Report

Download the Full 2022/2023 Beatbox sustainability report

Learn more about how BeatBox has been advancing sustainability in the alcoholic beverage industry by downloading the full report.

B Corp Certified and Plastic Neutral

BeatBox is now proudly B Corp certified and plastic neutral, reflecting its commitment to sustainability and responsible business practices in the alcoholic beverage industry.

The fastest-growing alcohol beverage company in the U.S. is now B Corp certified, plastic neutral, and carbon neutral.

BeatBox Beverages (BeatBox), headquartered in Austin, Texas, is the fastest-growing alcohol beverage company in the United States (US), with nearly 60 million BeatBoxes sold in 2023 alone. The brand was founded and is led by friends Justin Fenchel, Aimy Steadman, and Brad Schultz, along with original co-founders Jason Schieck and Dan Singer. BeatBox was one of the early players in the RTD beverage space, launching its company in 2013 and raising one million dollars from Mark Cuban on Shark Tank in 2014. BeatBox is also the fastest-selling single-serve wine in the United States, the winner of the 2021 Brewbound Rising Stars award, and one of Ad Age’s 20 Hottest Brands in America 2024.

BeatBox has always differentiated itself in the market through a combination of brightly packaged boxes, delicious wine-based punch in classic flavors with a kick, and a community built around the brand and music. The company offers several product lines: wine- and malt-based Party Punch and Hard Tea, along with its ever-expanding lineup of flavors and variety packs.

“We are the change we have wanted to see in the alcohol industry, with everything from brand experience to product innovation to our responsible business model.”

Justin Fenchel, Co-founder and CEO

As the brand continues to grow, BeatBox is expanding on its sustainability journey—reducing its environmental impacts is important to the founders and its community. Customers have started to demand more from the brands they consume, and BeatBox has been on a mission since day one to be the most sustainable and socially responsible alcohol brand in the industry.

What’s New for 2022 & 2023

Since releasing its first sustainability report in June 2022, BeatBox has continued to make progress on its journey to be the most sustainable and socially responsible alcohol brand in the industry. This report has been updated for 2022 and 2023 to reflect progress made since the initial sustainability report. Some highlights include:

- B Corp Certification: In June 2023, BeatBox achieved B Corp certification with an overall score of 83.6, showcasing their commitment to high social and environmental performance.

- Carbon Neutral: BeatBox purchased carbon credits to offset its calculated greenhouse gas (GHG) emissions from 2022 and 2023.

- Plastic Neutral: BeatBox enabled the removal of significant amounts of plastic waste to upkeep its Plastic Neutral certification through its partnership with rePurpose Global.

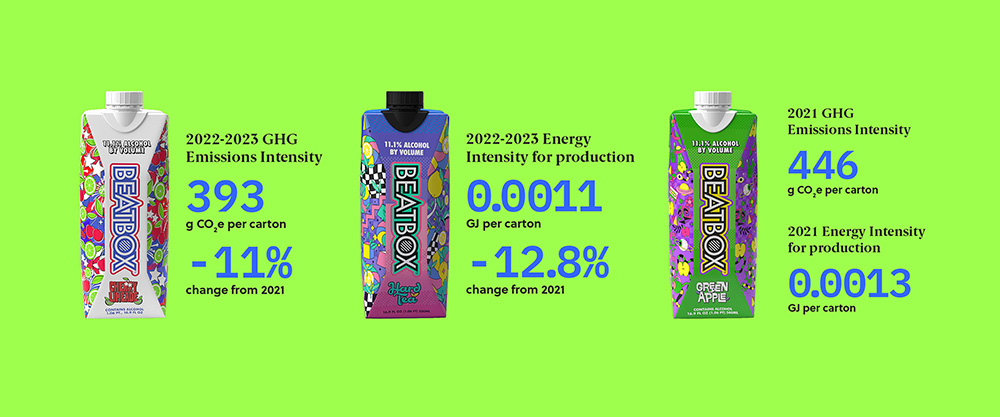

- Fuel Switching Project: In 2022, BeatBox collaborated with their Mexico co-packer to implement a fuel-switching project to adapt its boiler system to burn natural gas and also redirect excess heat from the boilers to a turbine system to generate electric power. The switch to natural gas from fuel allowed for a significant reduction in the energy and emissions intensity of production.

- BeatBus: In 2023, BeatBox introduced the BeatBus, enhancing marketing efforts and quantifying its travel emissions.

- New Co-Packer: An additional U.S. co-packer was onboarded in October 2022, increasing production capacity and reducing distribution distances.

- Expanded Production: In 2023, BeatBox increased production by 368%, reaching 71,027,628 units of 500 mL cartons and 79,242 units of 3L cartons compared to their 2021 production levels.

- Water Recycling: The co-packer in Mexico installed a new water recycling system in October 2023 for cleaning the exteriors of the facility and additional irrigation for their gardens.

BeatBox’s Sustainability Journey

BeatBox’s sustainability journey began during product development, with careful consideration given to ingredient and packaging choices. For example, some of BeatBox’s flavors are beet-based, with the beets sourced from Europe and North America in regions identified as high water-stress areas. These beets are mechanically harvested and cleaned before being processed into sugar, which is then transformed into the beet-derived flavor ingredient used in BeatBox’s beverages. Notably, apart from the water used for growing and washing the beets, no additional water is used in the production of this flavor ingredient, which aligns with BeatBox’s commitment to minimizing water use in its operations.

In 2020, the company built upon its sustainability efforts by committing to becoming plastic-neutral through a partnership with rePurpose Global, funding the collection, processing, and reuse of as much ocean-bound plastic waste as possible and matching the volume of plastic used across its packaging and operations. BeatBox also conducted a preliminary baseline of the carbon emissions associated with its operations.

In 2021, BeatBox implemented an Environmental Management System (EMS) to track its environmental progress, actions, and compliance. Some core elements of the BeatBox EMS include environmental performance goals, establishing roles and responsibilities for environmental actions, setting programs and actions to meet environmental objectives, improving data management procedures, and ensuring employees’ awareness of BeatBox’s environmental objectives.

With the implementation of its EMS, BeatBox ramped up efforts to assess its carbon, water, and waste footprints. The company fulfilled its commitment to disclose its environmental impacts publicly by publishing its first annual sustainability report, reflecting 2021 operations. This was a significant step for BeatBox on its journey to being the change they want to see in the alcoholic beverage industry, by being open and transparent about its impacts.

Since then, BeatBox has continued to make progress, including achieving B Corp certification in 2023 and purchasing carbon credits to offset emissions from 2022 and 2023. The company remains committed to continuous improvement and transparency in its environmental performance.

As part of its sustainability journey, BeatBox partners with the following organizations and companies to deliver on its sustainability goals while being an agent for change in the alcoholic beverage industry: The Climate Collaborative, Carton Council, Naturally Network, Naturally Austin, and CarbonBetter.

UN Sustainable Development Goals

The United Nations (UN) has published seventeen Sustainable Development Goals (SDGs) as a call to action to meet the UN’s 2030 Agenda for Sustainable Development goals. BeatBox’s environmental efforts directly support the following SDGs:

Operational Footprint

Headquarters & Team

BeatBox leases office space in Austin, Texas, which serves as a collaboration hub and meeting space, but BeatBox employees typically work remotely, cutting down on potential emissions associated with employee commutes. To help encourage environmental stewardship in employee home office spaces, BeatBox has incorporated remote working into its Environmental Policy and Green Office Policy.

Manufacturing

BeatBox uses third-party manufacturers (co-packers) to produce and package BeatBox Beverages. In 2022 and 2023, BeatBox expanded its manufacturing operations. Initially, the majority of BeatBox production was done by one co-packer in Mexico. In October 2022, BeatBox onboarded an additional co-packer in the U.S. to help increase production capacity and reduce distribution distances.

The co-packing facility in Mexico treats its own process wastewater using an activated sludge aerobic treatment plant to treat water efficiently while reducing chemical usage and exceeding its target removal efficiency with an annual average efficiency of 94%. The treated water is used on the co-packer’s agricultural fields and gardens to reduce irrigation demands and water stress on the local aquifer, and the sludge is used as compost. The co-packer maintains plants, raises goats and sheep, and they are focused on preserving the local forest surrounding its facility, keeping measurements of its tree planting and preservation efforts across a 12-hectare area.

In 2023, the co-packer in Mexico installed a new water recycling system to clean the exteriors of the facility and provide additional irrigation for their gardens. This system further enhances their ability to treat water efficiently and reduce chemical usage, contributing to the overall sustainability goals of BeatBox.

Marketing & Distribution

BeatBox’s marketing strategy includes attending music festivals, trade shows, conferences, and local events, with a focus on minimizing travel by targeting specific locations. For distribution, BeatBox works with a network of third-party distributors across the U.S. to bring its products to market. The company has significantly expanded its retail presence, growing from 23,000 stores in 2021 to over 100,000 stores by 2023. BeatBox also sells cases of its Hard Punch and Zero Sugar product lines, including variety packs, directly to consumers through its online shop. In 2023, BeatBox introduced the BeatBus and began tracking its travel routes to quantify emissions and further reduce its environmental impact.

Carbon Offsetting

To mitigate its environmental impact and achieve carbon neutrality, BeatBox has strategically invested in carbon offset projects that align with its geographic footprint and sustainability goals. In 2022 and 2023, BeatBox focused on projects that not only offset its GHG gas emissions but also provide meaningful co-benefits.

Project 1: Phlogiston Phase 1 Project

NITROUS OXIDE (N₂O) ABATEMENT PROJECT | USA

The Phlogiston Phase 1 Project, located in Cantonment, Florida, is the largest voluntary N₂O abatement project in North America. It focuses on removing N₂O, a potent greenhouse gas with a global warming potential almost 300 times greater than CO₂, produced as a byproduct of nylon manufacturing. The project also repurposes the manufactured nylon for use in high-performance flexible food packaging, which helps minimize food waste. This investment aligns with BeatBox’s commitment to offset emissions local to its orange wine source in Florida.

Registry:

UN SDGs:

.

.

.

Project 2: Patsari Improved Cookstove Project

IMPROVED COOKSTOVE AND COMMUNITY DEVELOPMENT PROJECT | MEXICO

To mitigate the environmental impact of its manufacturing activities in Mexico, BeatBox has invested in the Patsari Improved Cookstove Project. This initiative is located near the Monarch Butterfly BioSphere Reserve (MBBR) and provides the local community with safe, efficient cookstoves. These cookstoves use 60% less wood, which reduces carbon emissions, prevents deforestation, and protects natural habitats in the MBBR. The project also aligns with seven United Nations Sustainable Development Goals (SDGs), offering significant co-benefits such as promoting economic growth, providing affordable and clean energy, and improving air quality through more efficient burning.

Registry:

UN SDGs:

.

.

.

Goals & Improvements

BeatBox is dedicated to using the best ingredients to ensure the highest quality and most enjoyable taste in every carton while upholding its commitment to the environment and reducing its impacts.

Through the implementation of its EMS, BeatBox has taken significant steps to align its suppliers with its Environmental Policy. This includes evaluating the sourcing of ingredients as close to its co-packer as feasible to minimize the environmental impact of ingredient transport.

BeatBox has been actively supporting its Mexico co-packer in implementing clean energy projects at the facility. Key initiatives include adapting the boiler system to burn natural gas and redirecting excess heat from the boilers to a turbine system to generate electric power. The facility has also set goals to reduce its water impacts and save water in the packing process. A new water recycling system was installed in 2023 to clean the exteriors of the facility and provide additional irrigation for their gardens. The co-packer is currently evaluating opportunities to install a filtration system to replenish the aquifer.

BeatBox remains committed to continuous improvement and transparency in its environmental performance, striving to set measurable impact reduction targets and disclose its progress openly. As part of this journey, BeatBox will continue to innovate and expand its product offerings, maintaining its position as a sustainability leader in the alcoholic beverage industry.

Download the complete report below.

Download the full 2022/2023 BeatBox Sustainability Report

Learn more about how BeatBox is the change they want to see in the alcoholic beverage industry by downloading the full report.