A Quick Guide to Life Cycle Assessments (LCAs)

LCAs help businesses measure environmental impact from start to finish. Here’s how.

Sustainability has become a strategic priority for businesses across industries, and organizations are increasingly seeking ways to measure and minimize their environmental impact. One of the most effective tools for achieving this is a Life Cycle Assessment (LCA)—a systematic methodology that evaluates the environmental aspects and potential impacts associated with a product, process, or service throughout its entire life cycle. LCAs enable organizations to make informed sustainability decisions, improve efficiencies, and meet regulatory and stakeholder expectations. This blog post will explore what an LCA is, its methodology, benefits, and challenges, and how businesses can leverage this tool to improve operational inefficiencies and make them more sustainable and environmentally friendly.

What is a Life Cycle Assessment (LCA)?

A Life Cycle Assessment (LCA) is a scientific approach used to quantify the environmental footprint of a product, service, or process across its entire life cycle. The goal is to identify and evaluate environmental impacts, such as carbon emissions, water consumption, energy use, and resource depletion. By analyzing the full life cycle—from raw material extraction to disposal—organizations can better understand their environmental impact.

The Four Phases of an LCA

Conducting an LCA involves four distinct phases, as outlined below.

1. Goal and Scope Definition

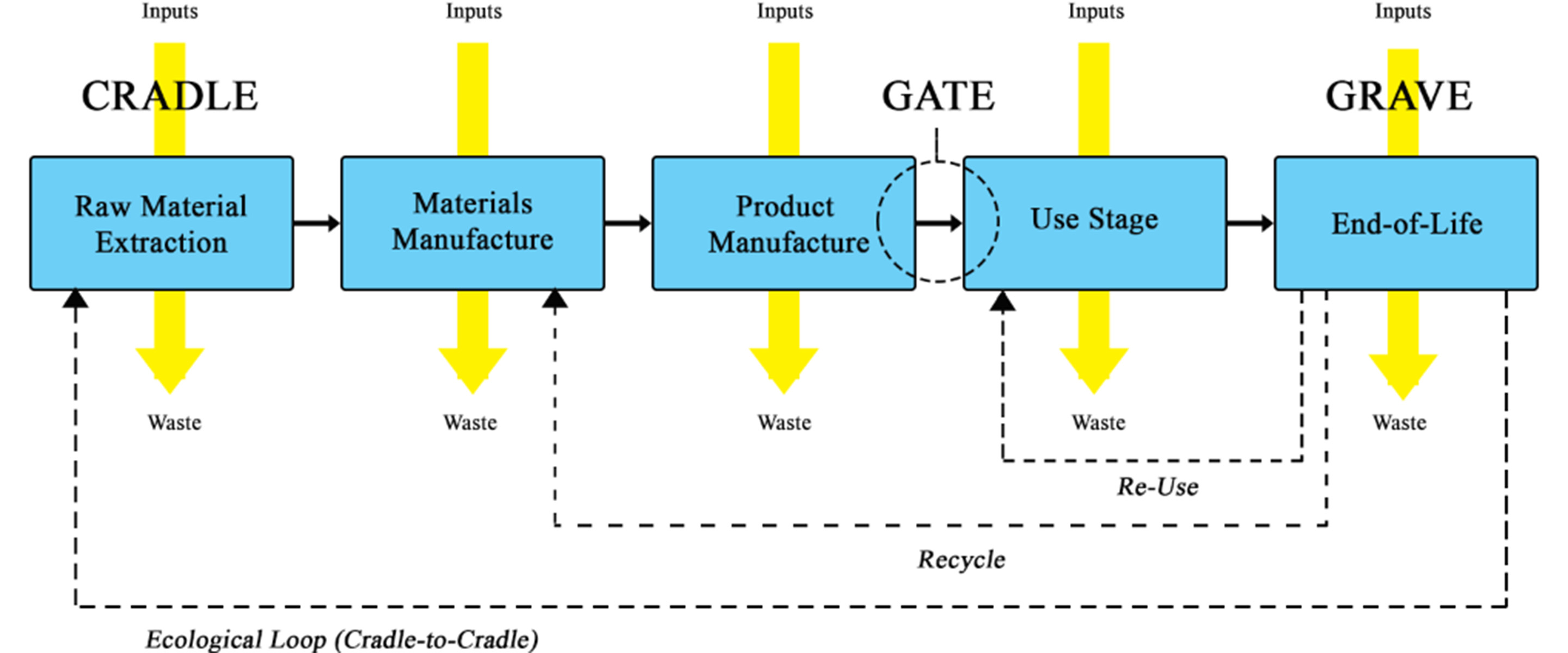

The first step in conducting an LCA is to clearly define its purpose and objectives. This includes identifying the functional unit—the measurable reference for what’s being analyzed, such as 1,000 liters of bottled water or one year of vehicle use. It also involves setting the system boundaries to determine which life cycle stages will be included (e.g., cradle-to-grave or cradle-to-gate), and selecting relevant impact categories, such as greenhouse gas (GHG) emissions, water use, or energy consumption.

2. Life Cycle Inventory (LCI) Analysis

This phase involves gathering detailed data on all inputs and outputs associated with each stage of the product’s life cycle. Inputs include materials and energy used, while outputs cover emissions and waste generated. Key stages analyzed typically include raw material extraction, manufacturing and production, distribution and transportation, the use phase, and end-of-life disposal through recycling, waste management, or landfill. This comprehensive data forms the foundation for evaluating the environmental impacts in the next phase.

3. Life Cycle Impact Assessment (LCIA)

In this stage, the data collected during the inventory phase is evaluated to understand its potential environmental impacts. The process begins with classification, where emissions and resource use are organized into categories such as climate change, air pollution, or water scarcity. Next, characterization uses scientific models to quantify these impacts—for example, converting various GHG into CO₂-equivalents. Normalization and weighting may also be applied to compare results against benchmarks or to prioritize impact areas, though these steps are optional.

4. Interpretation

The final phase focuses on analyzing the results to uncover opportunities for reducing environmental impact. Organizations use these insights to inform decisions such as selecting more sustainable materials, improving manufacturing efficiency to lower emissions, redesigning products for better recyclability, and refining logistics to reduce transportation-related impacts. This step ensures that the LCA findings translate into actionable strategies that support broader sustainability goals.

“LCAs enable organizations to make informed sustainability decisions, improve efficiencies, and meet regulatory and stakeholder expectations.”

Johanna Soerbom, Manager, Climate Services

🌍 Carbon markets can feel overwhelming—fragmented data, limited transparency, and conflicting advice make it hard to know where to start. In this webinar, our experts give a clear, practical introduction to the VCM.

Types of LCA Approaches

There are several LCA methodologies tailored to different business objectives. Cradle-to-Grave assessments evaluate the full life cycle of a product, from raw material extraction to final disposal. Cradle-to-Gate focuses on the stages leading up to the product leaving the factory, excluding use and end-of-life impacts. Cradle-to-Cradle supports circular economy goals by ensuring materials from used products are recovered and reused in new ones. Gate-to-Gate narrows the scope further by analyzing a single stage within the production process. Each approach offers unique insights depending on the assessment’s goals.

Benefits of Conducting an LCA

Conducting a Life Cycle Assessment offers several strategic benefits for businesses working toward sustainability targets. It enables improved decision-making by highlighting areas where emissions, waste, and resource use can be reduced. LCAs also support compliance with evolving regulations, such as the EU Green Deal, SEC climate disclosure rules, and ISO standards. Beyond regulatory alignment, they help build credibility with stakeholders by enhancing transparency around environmental impacts. Additionally, LCAs often uncover opportunities for cost savings through more efficient use of materials, energy, and logistics.

Conclusion

At CarbonBetter, we can help your organization conduct a Life Cycle Assessment that aligns with your sustainability goals, regulatory requirements, and operational priorities. Our team brings expertise in navigating complex supply chains, leveraging industry-leading tools, and translating technical findings into actionable strategies. Whether you're assessing a single product or building a broader decarbonization roadmap, we tailor each assessment to your unique needs—helping you make informed decisions and drive measurable impact. Reach out to explore how we can support your sustainability journey.

If your organization is preparing to conduct an LCA, we’re here to help. Contact us today to get started.

The timeline for completing an LCA depends on the complexity of the product or process being analyzed, the scope of the assessment, and the availability of data. A simple cradle-to-gate LCA for a single product might take a few weeks, while a comprehensive cradle-to-grave assessment involving multiple stakeholders and data sources can take several months.

An LCA requires detailed input and output data for every stage of a product’s life cycle. This includes raw materials used, energy and water consumption, emissions generated, transportation logistics, product use patterns, and end-of-life disposal methods. High-quality, accurate data—either collected internally or sourced from databases like Ecoinvent—is critical for reliable results.

LCAs are most commonly used for physical products, but they can also be applied to services. For example, assessing the environmental impact of a logistics operation or a cloud-based software service can provide insights into emissions, energy use, and resource consumption associated with service delivery.

The choice depends on your goals. If you're interested in understanding the full environmental impact of a product over its entire life, cradle-to-grave is ideal. If you're focused on production efficiency or supplier performance, cradle-to-gate may be more appropriate. Cradle-to-cradle is suited for circular economy goals, while gate-to-gate works well for analyzing a specific process within a larger system.

Yes. Conducting an LCA can support compliance with emerging environmental regulations and standards, such as the SEC’s climate disclosure rules, ISO 14040/44, the EU Green Deal, and California’s SB 253. It also demonstrates a proactive approach to sustainability, which can improve investor confidence and stakeholder trust.