Our Supply Chains are Optimized, but for the Wrong Things | Super Wicked Problems

Super Wicked Problems

A ‘wicked problem’ is “difficult or impossible to solve because of incomplete, contradictory, and changing requirements that are often difficult to recognize, and there is no single solution to the problem.” (Wikipedia) ‘Super wicked problems’ also include these factors: “time is running out; those who cause the problem also seek to provide a solution; the central authority needed to address it is weak or non-existent; and […] policy responses discount the future irrationally.” (Levin, K., Cashore, B., Bernstein, S. et al.)

What the 50,000-mile journey of a tennis ball can teach us about solving climate change

I believe we’ve reached a consensus that climate change is a pretty tricky problem to solve. In fact, climate change has all of the characteristics of a ‘super wicked problem’ (see sidebar). Despite its complexity, I believe that the more we understand the problem, the more likely it is that our solutions will be up to the challenge to solve it. In this context, let’s talk about supply chains. A supply chain is a network between a company and its suppliers to produce and distribute a specific product or service. The best companies have highly optimized supply chains with complex considerations. There are countless inputs, a ton of analysis is done, and contracts are made. It’s a feat to deliver the best possible product to consumers at the best possible price, which consumers demand.

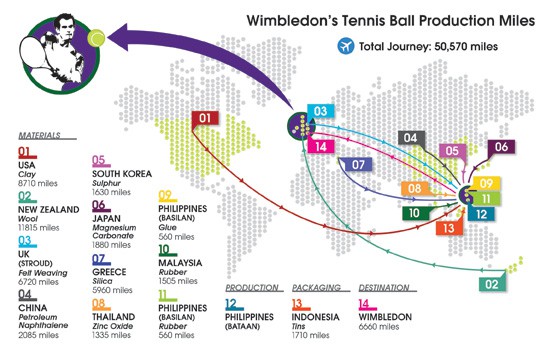

It can be difficult to paint an accurate picture of this specialized part of business, but Mark Johnson, an associate professor of operations management at Warwick Business School (WBS), did a solid job when he analyzed the raw materials and manufacturing journey of a single tennis ball for the Wimbledon championships.

The ball and its components travel more than 50,000 miles between eleven countries and four continents before being assembled in the Philippines and then sent to London.

This supply chain may produce the best possible product at the best possible price, but what it does not consider are its environmental impacts.

Rethinking the supply chain to consider environmental impact is an incredibly difficult and complex task. Would our tennis balls be so well-traveled if the climate was a consideration when they were developed? Would consumers pay a higher price that does consider climate impacts if it has to be made the same way? Factors and considerations like these are what contribute to making climate change a super wicked problem. Fighting climate change means rethinking how and why we do everything.

At CarbonBetter, we work with our clients to push the boundaries of their businesses in order to create real change. We believe that what’s good for our planet is good for business, and we work with our clients to find this alignment in their business practices. Because of our unique and deep expertise in the energy sector, we’re also able to work with the largest emitters to help them form effective strategies that ensure business success as well as protection for our planet.

This is not easy work, but it’s the work that will save our planet.

Tri is the founder and President of CarbonBetter. He expanded his energy business beyond logistics to help tackle climate change from the inside. When he’s not helping his team support energy and decarbonization clients, you can find him spending time with his family. Connect with Tri on LinkedIn and subscribe to be notified about new stories.