Carbon Emissions Intensity Explained

🌍 Carbon markets can feel overwhelming—fragmented data, limited transparency, and conflicting advice make it hard to know where to start. In this webinar, our experts give a clear, practical introduction to the VCM.

The metric that will give context to your total emissions as your business and carbon footprint both expand.

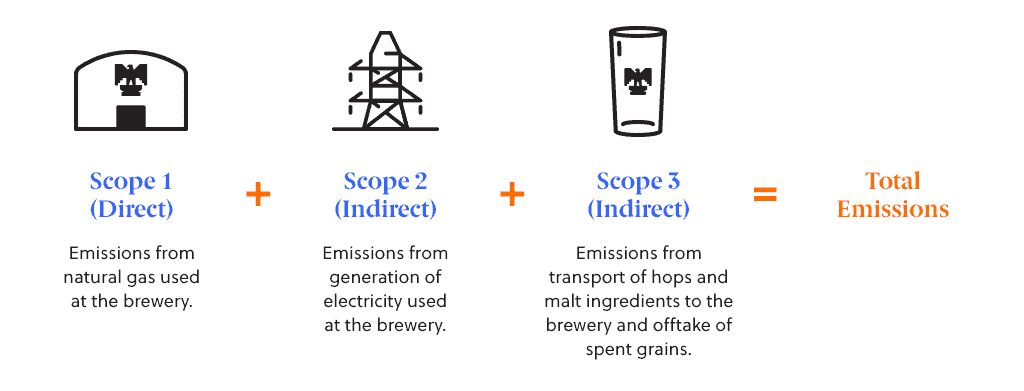

With consumers increasing pressure on companies to deliver more value while simultaneously reducing emissions, how can you set goals to reduce your carbon emissions when your business—and therefore carbon footprint—is expanding? Many organizations only look at total emissions, measured in Scope 1 (direct), 2 (indirect), and 3 (everything else in the supply chain), when setting and tracking emissions reduction goals. But there’s another metric that more accurately reflects improved business processes that reduce the amount of carbon emitted per product or unit even as total emissions increase.

That metric is emissions intensity, often measured in kilograms (kg) or grams (g) of carbon dioxide equivalent (CO2e) emitted per product. Water intensity and energy intensity can also be measured in this way, depending on which environmental impacts are material for your business. Another benefit of using emissions intensity is that it makes these numbers more relatable to consumers.

What Is Carbon Emissions Intensity?

Carbon emissions intensity refers to the emissions attributed to a facet of an organization’s operations. It’s calculated by dividing the total emissions by a metric of an operation, such as the number of products/units produced, the number of full-time equivalent employees, or the square footage of building(s). So if you’re making a product, emissions intensity might be in kg or g of CO2e per item that you manufactured. Or if you are an office-only type of operation, and your footprint is limited to the emissions associated with your office, carbon intensity might be measured in terms of full-time employee equivalents or emissions per square foot.

Why Does Carbon Emissions Intensity Matter?

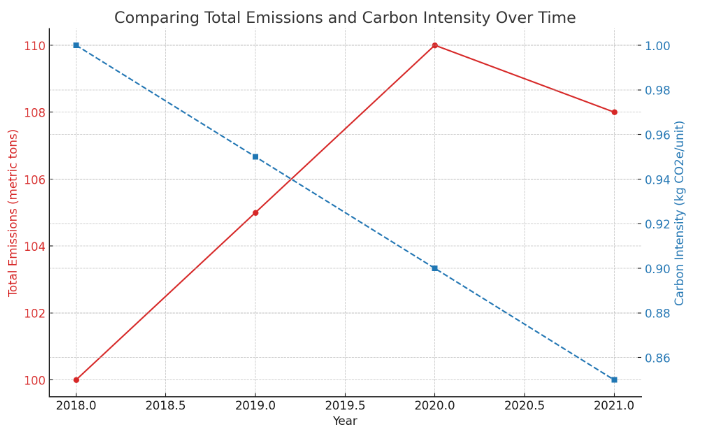

Carbon emissions intensity will vary from operation to operation, but it’s a really important way of relating emissions to where an organization is at scale. Companies that have set targets have likely set some sort of target around overall emissions. For example, a target to reach net zero by 2040. However, something that’s important to consider is that as an organization grows, its overall carbon footprint could also grow, particularly in the absence of energy efficiency projects.

For example, an organization might add a second or third facility or new suppliers, and even if they’ve done efficiency projects, they might still see an increase in emissions. There are various reasons for this. Maybe they’re now operating 24/7 whereas they used to only operate five days a week. Or maybe they’ve added new carbon-emitting equipment to their operations or have increased fuel consumption. Whatever the case, overall emissions could continue to grow as an organization grows, depending on what’s being done to mitigate those emissions.

Conversely, if you are working towards decarbonizing, your emissions intensity could actually go down as you scale up since emissions intensity accounts for your overall emissions in relation to your increased production or increased scale. So, in addition to total emissions targets, it can be helpful also to set emissions intensity targets. Carbon intensity gives context to total emissions by relating those emissions to a tangible product or unit.

Below is a table showing how carbon emissions intensity relates to total emissions, and how both are used together to get the full picture of an organization’s carbon emissions:

| Metric | Definition | Importance | Examples | Reduction Strategies |

| Total Emissions | The aggregate quantity of GHG emissions produced by an organization, encompassing direct emissions (Scope 1), indirect emissions from purchased electricity (Scope 2), and all other indirect emissions (Scope 3). | Essential for understanding the full scope of an organization’s environmental impact and for setting broad reduction targets. | A manufacturing plant’s combined emissions from its operations, electricity use, and supply chain activities. | Implementing renewable energy sources. Enhancing supply chain sustainability. Investing in energy-efficient technologies. |

| Carbon Emissions Intensity | The amount of carbon dioxide equivalent (CO2e) emitted per unit of economic output or activity, allowing for comparison of emissions efficiency across different scales of operation. | Provides insights into the efficiency of an organization’s operations, enabling targeted improvements and facilitating communication of progress in relatable terms. | CO2e emitted per liter of beverage produced by a company. CO2e emitted per square foot of retail space. | Optimizing production processes for efficiency. Adopting cleaner, less carbon-intensive sources. Engaging in carbon offsetting and insetting projects. |

| Importance of Dual Tracking | Tracking both total emissions and carbon intensity offers a holistic view of an organization’s environmental impact and progress toward sustainability. | Enables organizations to identify not just how much they are emitting, but how efficiently they are operating, highlighting areas for improvement and innovation. | A tech company reduces its total emissions by switching to renewable energy, while also lowering its emissions intensity by improving server efficiency. | Setting clear, measurable goals for both emissions reduction and improvements in emissions intensity. Regularly reviewing and adjusting strategies based on performance data. Engaging stakeholders in sustainability efforts. |

Your Action Items for 2040 Net-Zero

Over 702 companies on the Forbes 2000 have made net-zero pledges. Whether your organization has made a pledge or plans to make one soon, there's a massive difference between pledging net-zero and achieving it. Do you have a clear roadmap for your sustainability journey? What are the right steps to consider to achieve 2040 net-zero carbon, water, and waste goals? It's time to create a clear roadmap.

BeatBox Emissions Intensity Case Study

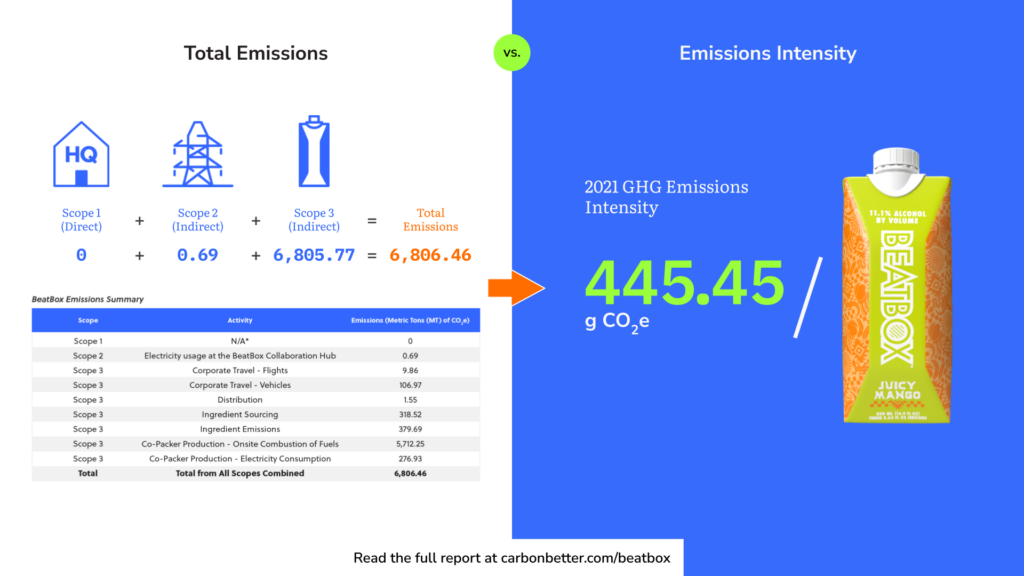

Here is a chart showing BeatBox’s 2021 emissions, including the carbon intensity per carton of party punch. On the left you'll see their total carbon footprint for Scope 1, 2, and 3 emissions. Since BeatBox actually uses a co-packer, in their case, the bulk of their emissions is in Scope 3, with total emissions measuring just over 6,800 metric tons of CO2e.

For consumers of products, a metric ton is really hard to visualize. (Even for people working in carbon accounting, it’s hard to visualize a metric ton). But when carbon emissions can be related in terms of the end-user product or service, it's much easier to digest. In the case of BeatBox, they have an emissions intensity of 445 g of CO2e per carton of party punch.

As mentioned above, the concept of emissions intensity is not just important from a progress-tracking perspective. It's actually also a really important tool to relate to consumers and help them really understand the impacts of this thing that they're consuming.

Strategies for Reducing Carbon Emissions Intensity

The following is a list of some of the more common ways to reduce your organization’s carbon intensity. This list is not comprehensive in covering every strategy, and expert guidance will be needed to implement these strategies effectively.

- Process Optimization: Streamlining operations to minimize waste and improve efficiency, thereby reducing emissions per unit of output.

- Energy Efficiency: Upgrading to more energy-efficient machinery, lighting, and heating, ventilation, and air conditioning (HVAC) systems to lower energy consumption and emissions.

- Renewable Energy Transition: Shifting from fossil fuels to renewable energy sources, such as solar, wind, or hydro, to power operations with lower carbon emissions.

- Product Design and Innovation: Developing products that require less energy to produce or that have a lower carbon footprint over their lifecycle.

- Employee Engagement and Training: Encouraging sustainable practices among employees and providing training on how to reduce emissions in their daily activities and work processes.

- Supply Chain Management: Working with suppliers to reduce emissions in the supply chain, including selecting suppliers with lower emissions intensity and collaborating on sustainability projects.

Conclusion

Most of the organizations we encounter know they need to measure their total carbon emissions, but it's not typically common knowledge what emissions intensity is or why it matters. If you’re unsure how to measure your organization’s emissions intensity or have other questions, reach out to our climate services team to learn more today.

Carbon emissions intensity refers to the amount of carbon dioxide (CO2) emitted per unit of economic output or activity. It can be measured in a variety of ways, such as CO2 emissions per unit of gross domestic product (GDP), CO2 emitted per passenger-kilometer traveled, or CO2 emitted per liter of beverage produced by a company. For example, a beverage company might measure the carbon emissions intensity of its products by calculating the amount of CO2 emitted per liter of beverage produced.

Carbon emissions intensity is important because it allows us to measure progress in reducing carbon emissions, even as total emissions may continue to increase. By reducing emissions intensity, countries and companies can become more environmentally sustainable and reduce their impact on climate change. For example, if a company's total carbon emissions increased over a certain period, but its emissions intensity decreased during that same period, it would indicate that the company is becoming more efficient and reducing its carbon footprint.

Reducing carbon emissions intensity can be achieved through various methods. One way is to increase energy efficiency, such as improving the energy efficiency of buildings, transportation, and industrial processes. By doing so, less energy is required to produce the same amount of economic output, resulting in lower carbon emissions intensity. Another method is to switch to renewable energy sources like wind, solar, and hydropower. These renewable energy sources produce fewer carbon emissions compared to using fossil fuels, hence reducing carbon emissions intensity. Carbon capture and storage (CCS) technologies are also helpful in reducing carbon emissions intensity by capturing carbon emissions from industrial processes and storing them underground, reducing the amount of CO2 released into the atmosphere. Overall, reducing carbon emissions intensity requires a combination of policy, technology, and behavioral changes.

About the Author

Pankaj Tanwar is Managing Director of Climate Services at CarbonBetter. He has experience leading Fortune 100 companies through their sustainability journeys, including sustainability driven growth in the food industry. Pankaj holds an MBA from Northwestern University’s Kellogg School of Management and a BTech in Mechanical Engineering from the Indian Institute of Technology, Kanpur.