Phlogiston Phase I N2O Abatement

🌍 Carbon markets can feel overwhelming—fragmented data, limited transparency, and conflicting advice make it hard to know where to start. In this webinar, our experts give a clear, practical introduction to the VCM.

Certified Offset Portfolios

Buying high-quality carbon offsets has never been easier. Explore CBCO Portfolio 22-1 and get instant access to fully vetted carbon offsets.

CBCO 22-1 Project Feature: Phlogiston Phase I N2O Abatement

Carbon offsets from the Phlogiston Phase I N2O Abatement project are included in CarbonBetter Certified Offset (CBCO) Portfolio 22-1, and this post shares more details about the project. Click here to read about other projects in Portfolio 22-1. Nitrogen dioxide, also referred to as nitrous oxide (N2O), is a greenhouse gas (GHG) that contributes to global warming. It is perhaps the lesser-known GHG as compared to carbon dioxide (CO2), but it is actually 265 times more effective at trapping heat in the atmosphere than CO2. The need to curb N2O emissions has largely flown under the radar until recently. CO2,methane, and N2O are “among the principal causes of human-induced climate change.”

Registered on the Climate Action Reserve (CAR) registry, the Phlogiston Phase I N2O Abatement project captures excess N2O emissions through a new absorption column at the Ascend Performance Materials’ adipic acid plant in Cantonment, FL. This is the largest voluntary N2O abatement project in North America, and it captures N2O byproduct emissions generated from nylon manufacturing.

Phlogiston Phase I N2O Abatement Offsets are Included in CBCO 22-1

CarbonBetter Certified Offset Portfolios allow you to participate in a variety of projects, geographies, and technologies in one simple transaction rather than navigating a lengthy and complex RFP process with multiple organizations.

Learn More About CBCO 22-1About Carbon Offsets

Carbon offset projects allow individuals, governments, and companies to reduce their carbon footprint by investing in climate-friendly projects located around the world through the purchase and retirement of carbon offsets issued by those projects. Not all carbon offset projects are created equal, but the carbon offset market is booming as more companies make commitments to sustainability and work towards net-zero.

A carbon credit is a financial instrument that represents ownership of one metric ton of CO2 equivalent that can be transferred, traded, sold, and ultimately retired. This credit represents an emission reduction or avoidance of one metric ton of CO2 or another GHG in CO2 equivalent (CO2e), and carbon emissions are “offset” once the carbon credit is retired. In 2020 alone, companies bought more than 93 million carbon credits. By 2030, the combined voluntary and mandatory carbon credit market could add up to $100 billion, a huge increase from $300 million in 2018. Purchasing carbon credits is how companies invest in carbon offset projects to reduce their carbon footprint.

We encourage organizations to reduce what they can and then offset the harder-to-abate emissions using carbon offset credits. The amount of emissions avoidance or sequestration that a carbon offset project can deliver is verified by the issuing carbon offset program, and carbon offset credits are then issued that entities can purchase.

Image courtesy of ascendmaterials.com.

Using Carbon Offset Credits to Reach Sustainability Goals

Companies make voluntary and/or mandatory sustainability commitments, depending on whether or not they are a regulated entity that’s required to participate in a carbon trading scheme. Regardless of the type of commitment, carbon offsets help companies become low-carbon or meet net-zero goals. Corporate climate commitments should address both direct and indirect carbon emissions, so buying carbon offset credits in combination with carbon reduction can be a smart strategy for decarbonization.

Phlogiston Phase I project was designed to destroy N2O emissions during the nylon manufacturing process so the GHG is not emitted into the atmosphere. Co-benefits of the project include reduced N2O pollution and GHG emissions into the atmosphere as well as overall improved air and water quality and ozone recovery.

About THE Phlogiston Phase I N2O Abatement PROJECT

EXPLORE THE SHAAN SEET PROJECT

The Shaan Seet Improved Forest Management carbon offset project contains over 8,900 acres of old-growth, hemlock-spruce forest, which provides critical ecosystem services including significant climate benefits through carbon sequestration.

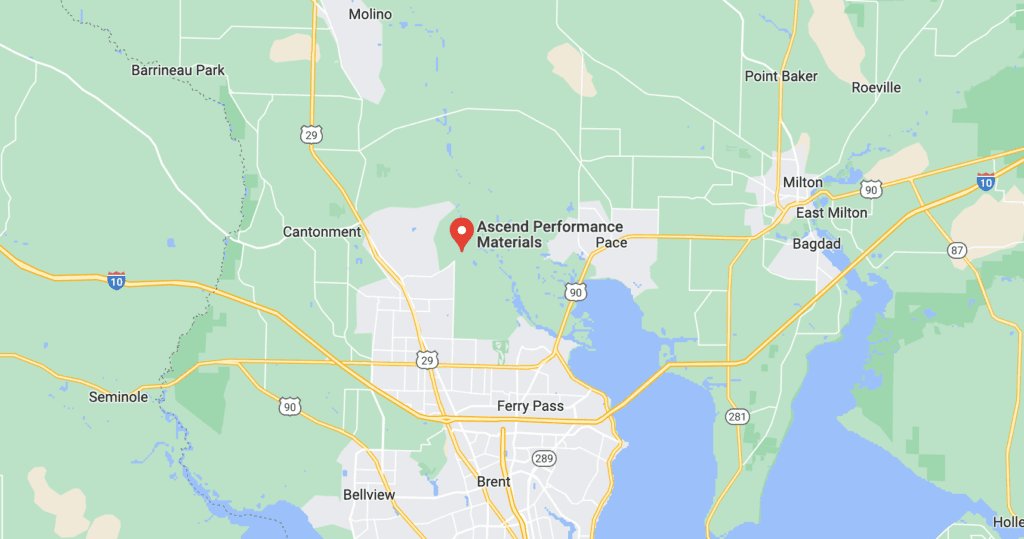

Project Location

The Phlogiston Phase I project is located at the Ascend Performance Materials plant in Cantonment, Florida, a community in Escambia County that is a suburb of Pensacola, Florida and within the metropolitan area. As of the 2020 census, the community has a population of 57,814 people and the area is 123.6 square miles.

Image courtesy of Google Maps.

Project Registry

Registered on the Climate Action Reserve (CAR) registry with a 2021 vintage, this industrial project destroys N2O—a greenhouse gas with 273 times the global warming potential of CO2—that is produced as a byproduct of nylon manufacturing. This is the largest voluntary N2O abatement project in North America.

UN Sustainable Development Goals

The UN SDGs that this project satisfies are:

- SDG 8: Decent work and economic growth

- SDG 9: Industry, innovation, and infrastructure

- SDG 12: Responsible consumption and production

- SDG 13: Climate action

Project Technology

N2O emissions are a byproduct of making adipic acid, which is commonly used to make nylon products. For every molecule of adipic acid produced, a molecule of N2O is produced as a byproduct. Most adipic acid produced in the world today is manufactured from cyclohexane feedstock in a two-stage process, where oxidation produces the N2O byproduct.

The Ascend plant recognized the need to capture emissions of nitrogen oxides (NOX) , a criteria pollutant, from escaping into the atmosphere during the production of nylon manufacturing. Before the installation of the current technology, exhaust from the adipic acid process was directed to a Selective Catalytic Reduction (SCR) unit that would destroy NOX as part of the plant’s obligations under the Clean Air Act. However, this process could not also abate N2O. A solution needed to be installed to handle both N2O and NOX scrubbing so the plant could meet its Clean Air Act obligations codified by the United States Environmental Protection Agency (EPA) and also abate N2O.

The Phlogiston Phase I project uses an enhancement of an existing control technology thermal reduction unit (TRU) at the adipic acid plant to abate N2O emissions. It allows the TRU to accept more waste from the adipic acid plant, resulting in a higher quantity of N2O abated. Phase I operations of the project began in early 2021 and anticipates N2O abatement of approximately 50% while achieving a nearly 98% abatement by the second phase.

The N2O concentrations are monitored using a continuous emissions monitoring system (CEMS). The reports are stored in electronic records for 10 years from the date of generation. The plant data acquisition system (DAS) includes a programmable logic controller (PLC), local computer, and server-based system used for CEMS data monitoring, recordkeeping, and reporting. The system monitors gas flow rates and N2O concentrations on a continuous basis.

The plant also monitors CO2 and methane emissions from the increased external energy use due to the N2O abatement process.

Image courtesy of insideclimatenews.org.

Project Co-Benefits

Phlogiston Phase I project was designed to destroy N2O byproducts during the nylon manufacturing process so the GHG is not emitted into the atmosphere. Co-benefits of the project include reduced N2O pollution and GHG emissions into the atmosphere as well as overall improved air and water pollution and ozone recovery. Additionally, this particular project has established a process that produces materials more sustainably, which helps reduce waste and work towards net-zero goals. The company also offers co-benefits by focusing on corporate sustainability. Ascend Performance Materials is committed to sustainability and leading the industry towards a more sustainable future. Through the Ascend Cares Foundation, the company and its employees help families in their times of need, provide opportunities for community engagement, and facilitate community leadership.

Want to be a part of the Phlogiston Phase I N2O Abatement story by purchasing carbon credits to support this project? CarbonBetter offers its innovative Certified Offset Portfolios for your offsetting needs. The portfolio includes vetted, certified, and verified carbon offset projects that also offer co-benefits for their host communities. Contact us today for more information.