Fierce Whiskers Distillery 2023 Sustainability Report

Download the Latest Report

Fierce Whiskers has scaled to full operation while cutting emissions intensity and boosting sustainability efforts in its latest report.

With the release of its third report, Fierce Whiskers leads the spirits industry by reducing emissions intensity and improving efficiency.

Fierce Whiskers (FW) is a unique American bourbon distillery that embraces the ethos of “greatness through stubbornness.” Making world-class whiskey is not easy, and doing so sustainably adds another layer of complexity. FW is focused on producing the highest quality whiskey, from grain selection to barrel aging and bottling, with an emphasis on efficiency throughout every step of its process. FW sources local grains whenever possible, utilizes low-impact Kelvin Cooperage white oak barrels for aging its whiskey, and has built a unique five-story rickhouse with louvers to leverage the harsh Central Texas climate in the aging process.

FW aims to be a foundational building block in the craft spirits world of Austin, Texas, while staying true to its roots in the local community. FW welcomes visitors to its tasting room and its six-acre distillery property daily and routinely hosts indoor and outdoor events featuring local musicians and a variety of food options from local chefs.

What’s New in the 2023 Report

Since breaking ground in 2018 and releasing its first sustainability report in September 2021, FW has continued to make progress on its journey to bring fantastic whiskey to Austin, Texas, while also furthering its commitment to environmental sustainability. This report has been updated for 2023 to reflect progress made since its 2022 sustainability report.

Since its initial report release, FW has been busy ramping up to full-scale operations. This growth increased its overall emissions, but they have successfully delivered an emissions intensity reduction from 2022 to 2023 by leveraging the sustainability strategies and energy efficiency built into every step of its operations. Download the full report for the data and calculations. Other highlights since the 2022 report include:

- Decreased emissions intensity year-over-year from 2021 through 2023, with increased operational efficiencies and a focus on energy management.

- The first main product release in 2023, expanding bottling and distribution while maintaining a commitment to sustainability.

- Ongoing participation in sustainability discussions, such as the “Brands Shaking Up Alcohol’s Carbon Footprint” panel, to share best practices in sustainable spirits production.

- FW generated 66,927 kWh of solar power in 2023, accounting for 9.1% of its total electricity consumption, reducing its reliance on non-renewable grid power.

- Launch of its online store, including merchandise like T-shirts and hats, in addition to its whiskey.

After years of development, FW released its first-ever bourbon, the Fierce Whiskers Texas Straight Bourbon, in May 2024. The craft distillery celebrated this milestone with a free-to-the-public bourbon bash at its six-acre Austin property, offering whiskey lovers a first taste of the new product. The Texas Straight Bourbon is now available for purchase at retail stores across Texas.

FW continues to prioritize superior taste and sustainability in every decision. As the distillery expands its product lineup, it remains focused on balancing water and carbon trade-offs in ingredient sourcing, optimizing energy and water use through monitoring and automation, and providing an exceptional experience at its property, where the Austin community gathers for music, food, and world-class whiskey.

“I think we are in a really special position that many companies that we compete against are simply not: We didn’t have to retrofit sustainability into our brand or our processes—we thought about it from day one, and it’s been pretty impactful in terms of our approach and how things happen.”

Co-Founder Tri Vo, on incorporating sustainability into operations

Grain to Glass

FW is focused on ensuring the highest quality of whiskey is produced, beginning with grain selection, barrel aging, and bottling. With 97.3% of its grains sourced from Texas, FW begins with milling regionally produced grains to create unique mash combinations for its whiskeys, including bourbon and rye. FW worked closely with a thirty-year Kentucky bourbon veteran to carefully select each piece of equipment, including a Kentucky-produced copper still and a custom rickhouse.

Throughout the distillation and aging process, FW has introduced its own techniques to leverage the extreme atmospheric conditions in Austin, TX, to produce a distinctly Texan whiskey. This includes improved efficiency of equipment using sophisticated automation systems that optimize quality control, consistency, and safety.

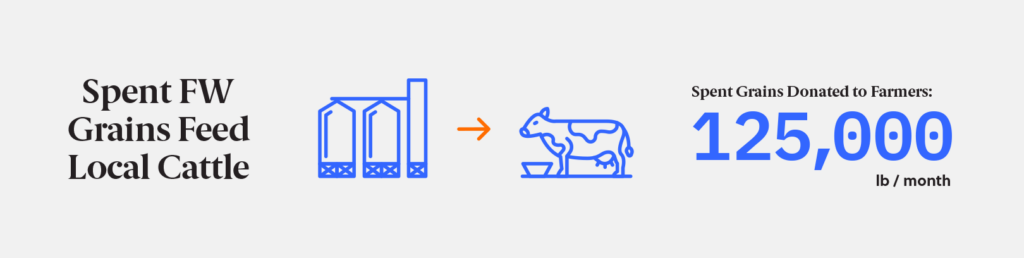

By weight, over 97% of the grains utilized by FW are produced near Amarillo, Texas. After production, FW demonstrates its commitment to participating in the circular economy by donating spent grains to local farmers to minimize waste and ensure reuse. Farmers utilize the spent grains as animal feed.

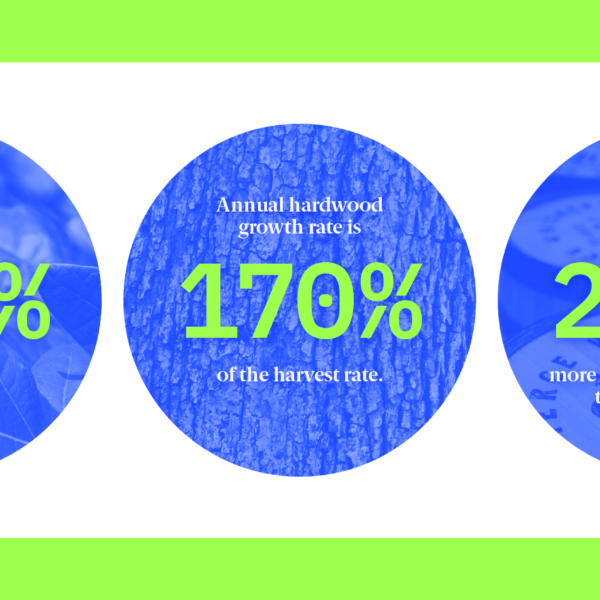

As with traditional American Bourbon, FW ages bourbon and rye in new white oak barrels for years at a time, giving its whiskeys distinctive and rich flavors. FW selected Kelvin Cooperage white oak barrels as Kelvin Cooperage ensures 100% of every white oak log purchased gets processed and utilized, with oak scraps being utilized in the toasting process as this can yield different oak profiles, and has created a used barrel program for reselling once-filled barrels and minimizing waste. Kelvin Cooperage is a member of the White Oak Initiative, which has contributed to white oak being the second fastest-growing hardwood resource, with an annual growth rate exceeding harvest by 70%.

Fierce Whiskers Launches World’s First Carbon-Negative Bourbon

The Austin distillery is releasing 257 carbon-negative bottles from Barrel #47 in a limited release.

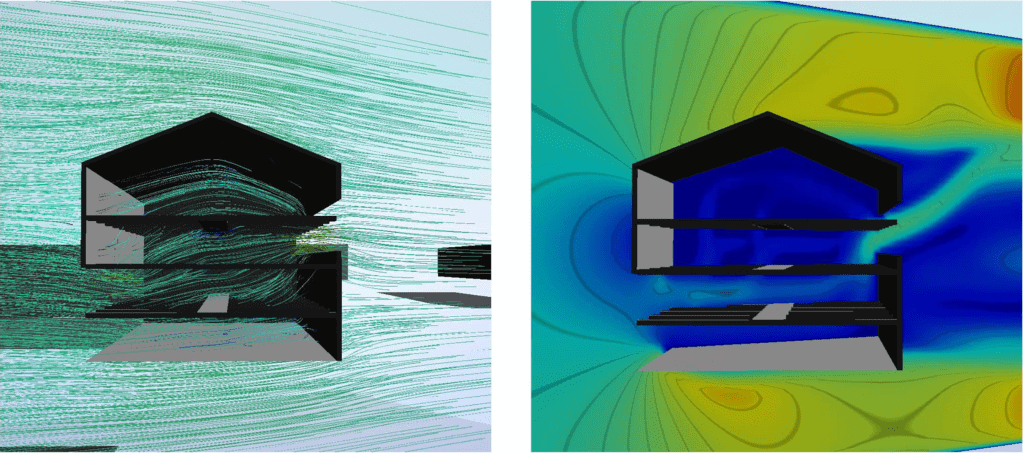

Harnessing the Texas Climate

The five-story bonded rickhouse, with four stories above ground and one below, is uniquely designed to allow FW more creative control over the flavor of its whiskey while harnessing the harsh summer climate conditions in Central Texas. FW selected the building location during the design phase based on the outcomes of a wind study, allowing the rickhouse to capture ideal prevailing winds. The louver system, with manual louvers on each side of the building, harnesses airflow to aid in temperature regulation. Typically, rickhouses have small windows rather than manual louvers. FW installed its own weather system to monitor temperature and humidity, allowing the distiller to make louver adjustments based on real-time weather data.

A natural ventilation analysis was conducted to optimize direct airflow and fast ventilation based on the main wind direction.

Energy Impacts

FW selected high-efficiency equipment, including a boiler with an industry-leading efficiency rating. They have also deployed automation systems to ensure efficiency and quality control over time. Facilities of this size do not typically have automation systems to this extent. As an example of FW’s commitment to reducing energy waste, doors are equipped with sensors to cut off the HVAC system when opened. Efficiency was considered throughout the distilling process, building operations, interior and exterior lighting, and the rickhouse. To further reduce the impacts of its energy consumption, FW installed a state-of-the-art solar project consisting of a rooftop solar array with a highly efficient inverter.

In 2023, FW’s solar array produced 66,927 kWh of electricity, covering 9.1% of its total electricity consumption. FW’s combined electric and gas energy consumption was 9,059 GJ.

Utilizing utility data from the start of operations through 2023, FW has quantified its energy and emissions intensity. Full data and calculations are included in the downloadable report, with a summary shared below.

A Continued Focus on Water & Carbon Tradeoffs

Austin’s climate is part of what makes FW’s aging process unique, but the summer climate also creates significant water demand for landscaping. FW follows the City of Austin’s conservation stage requirements, watering only one day a week between 7pm and midnight or midnight and 10am. To further reduce water use, FW is actively exploring rainwater collection as a potential option for landscaping.

While not directly linked to water consumption, FW is carefully considering the impacts of water on grain selection, balancing the decision to use locally produced grains from water-stressed regions. Currently, FW’s facility is billed based on total non-irrigation water discharged, which matches the water consumed, though this does not account for the water used in whiskey production and barreling. Moving forward, FW will continue monitoring its water use more closely by comparing the discharged water to the total water billed by the City of Austin to better reflect actual water consumption.

As in many sustainability choices, there is not a clear winner—selecting regionally produced grain from a water-stressed region adds to the complexity of FW’s decisions and is an important consideration moving forward.

The Future of the Brand

FW focuses on utilizing the best ingredients combined with a data-driven approach to ensure the highest quality and most enjoyable taste from each barrel. This means transparency in production and its sustainability efforts. Every decision revolves around uncompromising quality, all while improving energy efficiency and reducing environmental impact. As FW continues to ramp up production, it maintains its local impact, proudly serving Austinites, sourcing grains as locally as possible, and supporting farmers through its spent grain donation program. FW remains dedicated to continuous improvement, sharing data and progress every step of the way.

There’s more: download the fully updated report

Learn more about how Fierce Whiskers has made sustainable choices every step of the way by downloading the full sustainability report, which now includes Scope 3 emissions.